Package Pump Station Guide

Package Pump Station Guide.

There are many factors to buying a package pump station and trying to understand these can certainly become daunting at first. This blogs purpose is to provide a simplified explanation of the purpose and contents of a packaged pump station.

What is a pump station?

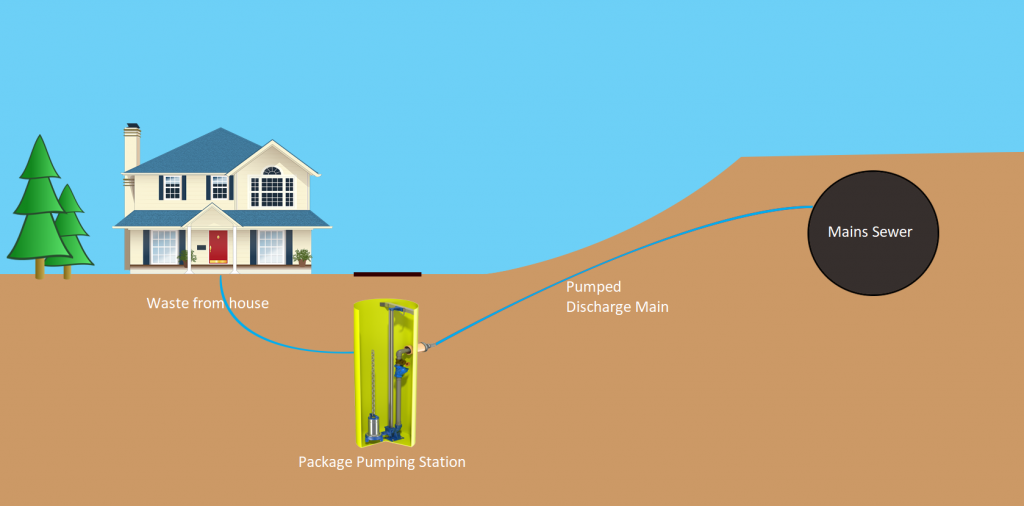

A pump station is a chamber fitted with pumps with the purpose of moving water from one place to another where the use of a gravity system is not available.

Pump stations can vary in size depending on how many properties and people it serves. As a general rule of thumb, residential houses produce 150litres of water per person, per day. Commercial buildings such as offices or factories will produce 50-60litres per person, per day.

[caption id="attachment_15" align="aligncenter" width="1024"] Illustration showing a residential home using a foul water package pumping station[/caption]

Illustration showing a residential home using a foul water package pumping station[/caption]

Whats in a package pump station?

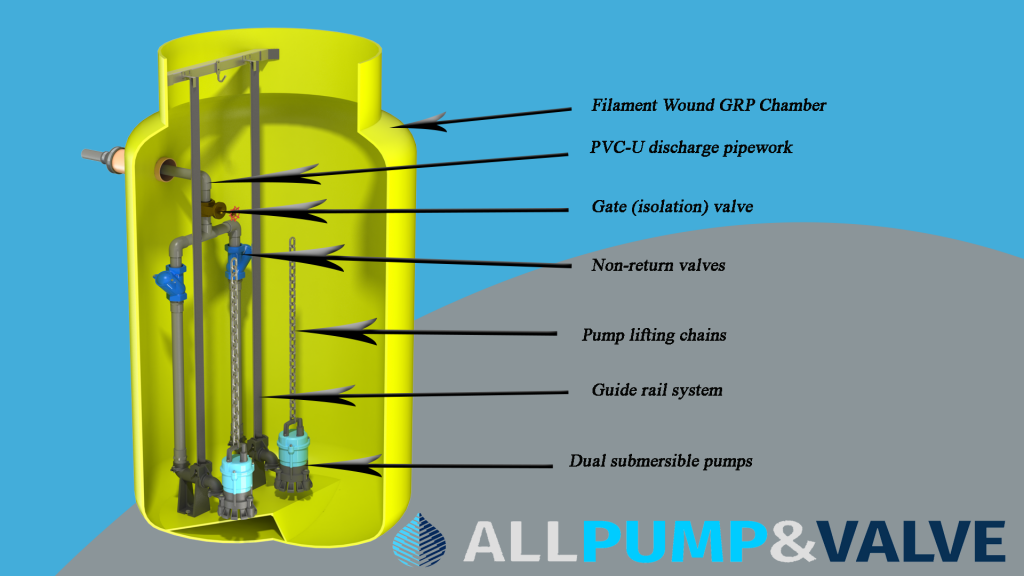

Pumps

The first answer probably won’t come as much of a surprise... Pumps. Pump Stations are most commonly fitted with one or two pumps and the latter option gives you a more reliable system. Dual pumps running in a duty/standby mode means that although only one pump will ever operate at any given time. You then have a secondary pump as a back-up should the first pump fail. When installed in conjunction with All Pump & Valve’s control panels, the duty pump is rotated so that you get even wear from the pumps.

Choosing the right pump for your station is one of the most important things to consider. All pumps work best at the centre of the pump curve and you are able to download the pump curves for any pump on our website. Please contact us direct for help choosing your pump and watch out for future blogs with pump selection tips!

Pump Controls

Most pump stations operate via the use of float switches. These can either be fitted directly to the pump which simply turns the pump on or off as the water rises and falls. With dual pump systems, the use of multiple floats allows you to adjust the minimum and maximum levels. It’s also possible to use a third and fourth level regulator for minimum and maximum alarm. The multiple float setup is then controlled using a control panel.

Valves and pipework

PVC pipework and valves are installed to suit the size of the pump. Non return valves are installed to prevent damage to the pumps from backflow and gate valves are installed to allow you to isolate the rising main to carry out any remedial works within the pump station. Non return valves tend to come as either ball valves or swing check valves, dependent on the type of application.

Guide Rail System

This is an optional system in which the pumps are fitted to a lifting chain and slide up and down a guide rail system to auto locate on their discharge foot at the bottom of the pump station. This is hugely advantageous and allows for very quick and easy removal of the pumps for servicing and repair needs.

[caption id="attachment_17" align="aligncenter" width="1024"]

Illustration showing the components commonly found within an All Pump & Valve package pump station[/caption]

Illustration showing the components commonly found within an All Pump & Valve package pump station[/caption]

Should you have any further questions or would like help in choosing the right package pump station for you, please don’t hesitate to use our chat feature or call us on 01743 452050 or email us at info@allpumpandvalve.com